Solution of electrodeposition coating for motorcycle electric bike

Product Introduction

| HR-4000BLB/HR-6000 the bottom of one black cathode electrophoretic

coating, is HLS Paint (Shanghai) Co., Ltd., the eighth generation

of independent research and development of electrophoretic coating. |

| This coating by epoxy acrylate modified, the film also has

excellent corrosion resistance and weatherability, smooth

appearance and full, suitable as a base topcoat system. In

addition, the lead, cadmium, chromium, mercury and other heavy

metals, two-component, water dispersible resin, at the same time,

previous generations of the product characteristics, have good

adaptability to the galvanized steel, almost can be applied to all

metal coating, such as: cold hot rolled steel, galvanized steel,

aluminum, zinc Aluminum Alloy plate, stainless steel plate. |

This product features shown below:

The appearance of the coating is flat, delicate, smooth.

Good stability of bath can adaptable for a longer updating cycle.

Have excellent corrosion resistance and weathering resistance,

especially suitable for the bottom surface of a painting

Main ingredients

| Matrix resin: | Acrylic modified epoxy resin |

| Curing agent | Fully enclosed multi isocyanate |

| Additives | surface active agent, prevent shrinkage cavity agent |

Product quality data

| Project | Technical data | Test standard |

Resin

(HR-4000BLB) | Black Paste (HR-6000) |

| Conductivity | 25℃, μs/cm | 1000±500 | —— | HG/T 3334 |

| pH | 25℃ | 6.0±1.0 | —— | GB/T 9724 |

| Appearance | —— | Milky white liquid | Black viscous liquid,no agglomeration | Visual |

| Storage stability |

No stratified state, and there were no obvious difference compared

to before storage | In 5-35 ℃ temperature 1 year |

Note: pH, conductivity measurement in the resin/pure water = 1:1

dilution

Bath on site management project

Good bath data and coating quality, from the strict parameters

management and maintenance of equipment, production line according

to its own reality time situation, can have different management

project and specifications, recommend the construction parameters

see the table below for reference:

| Classification | Project | Control Data | Testing frequency |

| New bath | Anolyte |

| Electrophoresis tank | Ratio | 1:(6-8) | -- | |

| Ripening time | 24-48 | -- | |

| Solid ( 120 ℃ /1h ,% ) | 15±5 | -- | once a day |

| PH | 5.4-6.0 | 2.0-3.5 | once a day |

| Conductivity ( μs/cm ) | 1000±500 | 1400±900 | once a day |

| P/B | 0.08-0.15 | once a week |

| L panel | Smooth horizontal plane and vertical plane without obvious

differences | once a week |

| Solvent content (%) | 0.5-1.8 | once a week |

| Liquid level Fall head (cm ) | 10-15 | once a day |

| ED voltage( V ) | 0-300 | once a day |

| Break voltage ( V ) | ≥350 | once a week |

| Bath temperature ( ℃ ) | 28-35 | once a day |

| ED time( S ) | 60~180 | once a day |

| UF - 1 Tank | Solid content (%) | ≤2.0 | once a day |

| UF - 2 Tank | Solid content (%) | ≤0.8 | once a day |

| Baking furnace | Provisions furnace temperature( ℃ ) | 170-190 | once a day |

| Curing conditions | Drying temperature |

(165-185)℃×(20-30)min (With content holding time) | once a day |

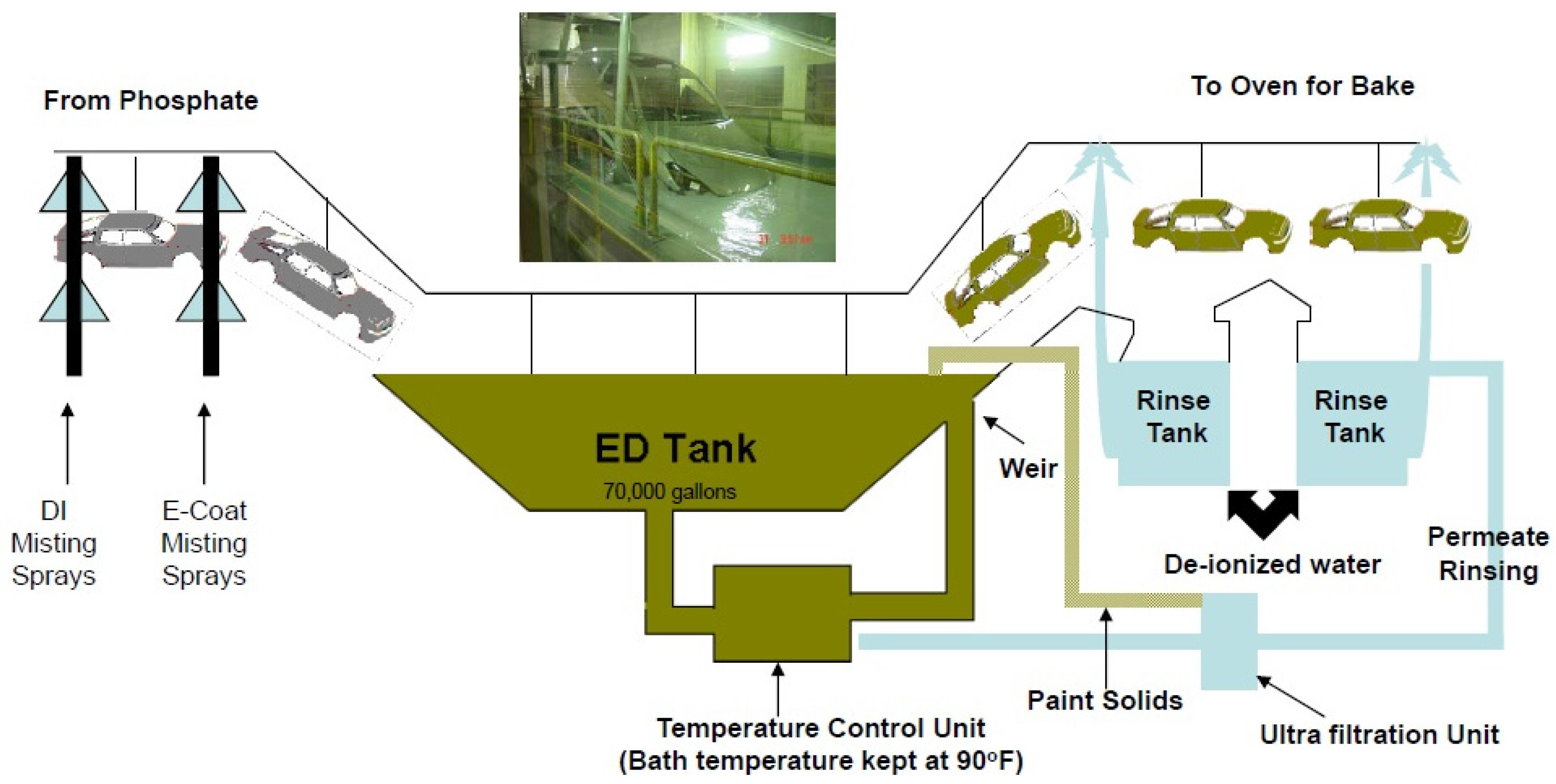

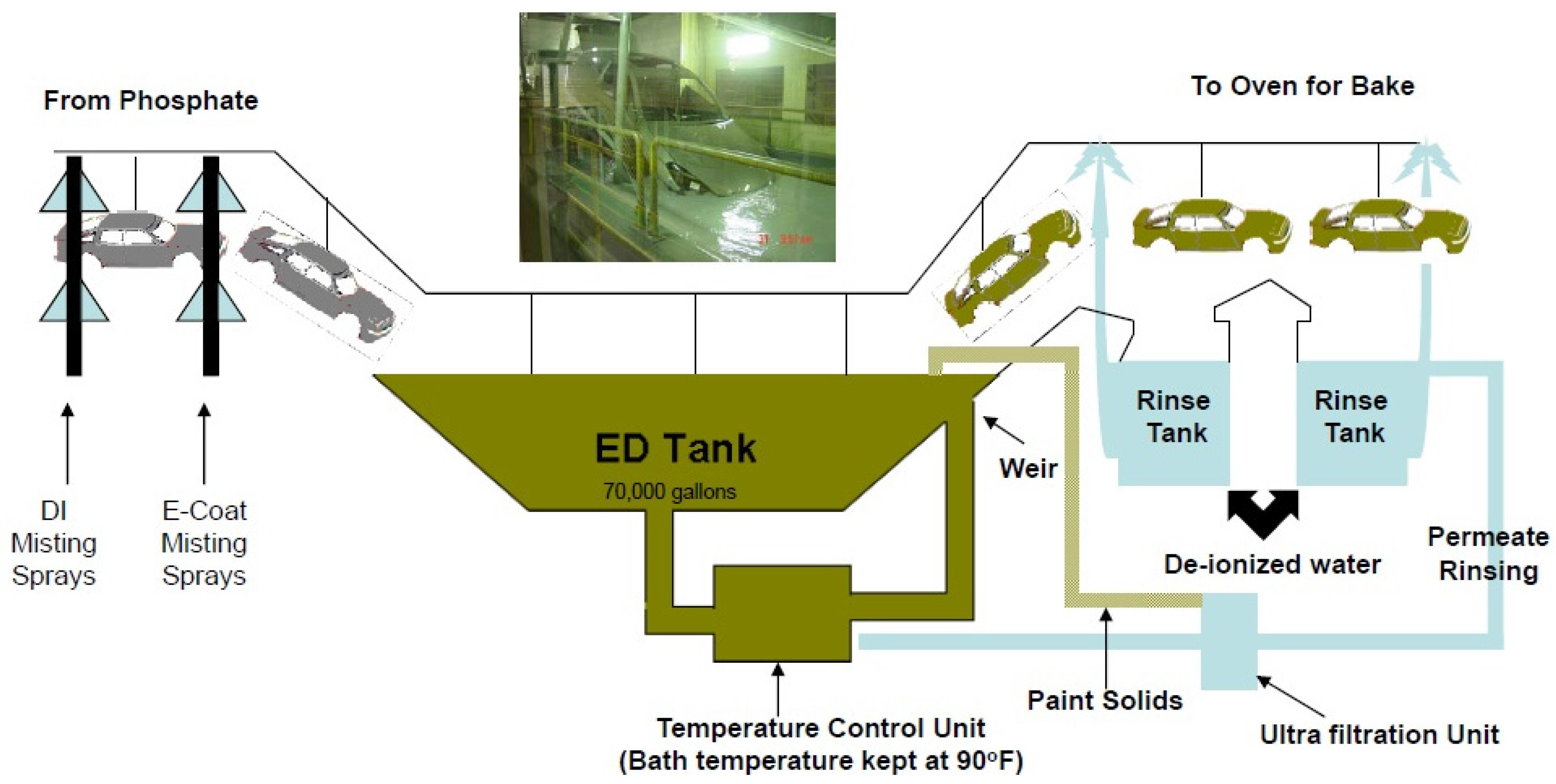

Construction equipment :

Cathodic electrophoretic coating construction in the

electrophoresis tank, so need to have the following equipment:

Electrophoresis tank

Circulation devices (including filter, fill the paint device)

DI water equipmen

DC power supply and the power supply unit

Anode box (tube) and circulation device

Ultrafiltration device

Cleaning devices

Heat exchanging equipment

Curing device

ED coating line: